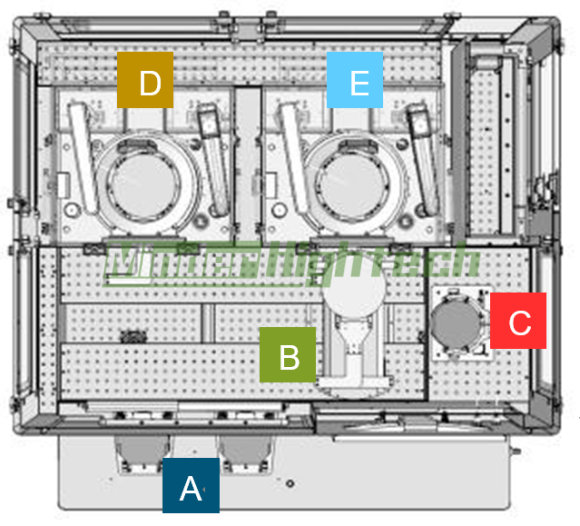

Fully automatic single-chip wafer cleaning machine

l Single cavity, two cavity, and four cavity

l Strong process capability, capable of supporting applications such as Wafer Start and process cleaning

l Good consistency of equipment inter chip technology

|

Application Fields |

l Surface particle removal of 4-8 inch silicon-based and compound based wafers

|

Technical parameters |

l 4-inch, 6-inch, 8-inch brush cavity

l Spinner speed up to 4000RPM

l Dual Arm brush chamber, available in Brush, AS, JET, Megasonics cleaning methods

A. LoadPort unit, loading unit

LoadPort is the loading unit of this device Capable of Wafer Mapping

Equipped with Wafer slide detection

B.Transfer Robot unit

Dual Blade Robot, optional with vacuum or tray type Blades.

C. Alignment and flipping unit

Can align and locate flat edges

Wafer can be flipped to scrub the crystal back

D/E. Brushing unit

Brushing Arm Quantity * 2

Wafer handle: Chuck clamp or suction type

Brush, AS, JET, Megasonics cleaning modes, supporting pharmaceutical cleaning

1. Supports Wafer input and output

simultaneously, as well asA input and B output modes

2. Can support brushing the front of chamber A andthe back of chamber B

3. Can support dual chamber parallel cleaning

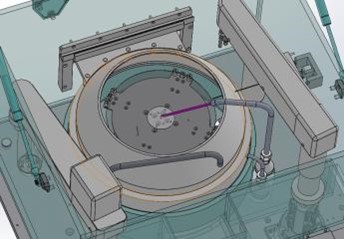

Brush unit description

As shown in the figure

Wafer fixed on top of Spinner

Arm1&Arm2 can be used in conjunction with various brushing methods described earlier to clean wafers.

After cleaning, Spinner rotates at high speed to spin and dry the wafer

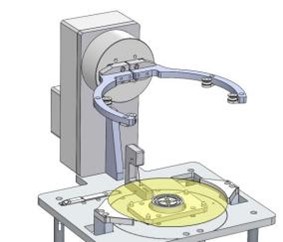

Alignment and flipping unit

Wafer can be used for residential and leveling purposes Wafer can be flipped

Equipment size: 160x150x220 (mm)

Loading and unloading methods: same in and same out&A in and B out

Number of brushing units: 2

Brushing modes: Brush, AS, JET, Megasonics cleaning methods, supporting pharmaceutical cleaning

联系人:胡顺语

手机:0086-15813334038

电话:020-84789496

邮箱:md@minder-hightech.com

地址: 广州市番禺区大龙街市新路新水坑段43号813