1.Application Areas

laser decapsulation system designed for precise and efficient removal of epoxy and plastic molding materials.

2.Laser Processing Principles

Laser processing technology focuses light energy through a lens to form a high-energy-density laser beam. Leveraging the interaction between the laser beam and matter, it performs cutting, engraving, welding, surface treatment, drilling, cleaning, and micromachining on materials (including metals and non-metals).

As an advanced manufacturing technology, laser processing has been widely applied in key sectors of the national economy, including automotive, electronics, electrical appliances, aviation, metallurgy, and machinery manufacturing. It plays an increasingly important role in improving product quality, increasing productivity, facilitating automation, and reducing pollution and material consumption. Across various fields, laser cutting, laser marking, and laser welding are the most widely used.

The laser decapsulation machine easily and conveniently removes the encapsulation layer from plastic-encapsulated semiconductor devices, exposing the lead frame on the substrate.

It features a fully graphical user interface for simple control.

It can easily handle full-surface, targeted, or even flat decapsulation of plastic encapsulation material, significantly reducing the amount of acid used and the time required for chemical decapsulation, while maximizing the success rate of decapsulation.

It is capable of decapsulating a variety of plastic-encapsulated devices, including integrated circuits and discrete components.

It also offers excellent decapsulation performance for gold, copper, aluminum, and silver wire encapsulation.

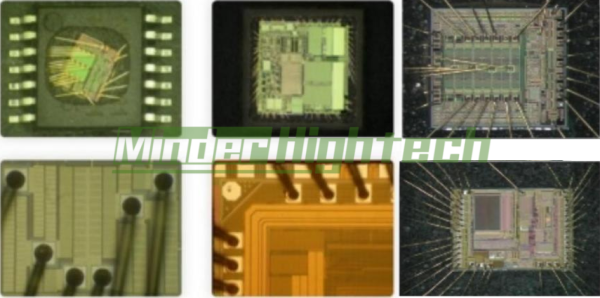

sample:

3,

Performance parameters

|

Number of laser heads/laser wavelength |

MOPA30W*1 set, 1064nm |

|

Optical configuration Parameter range |

Laser head focal length 160mm/110mm x 110mm Minimum opening area 0.1mm x 0.1mm Maximum opening area 300mm x 300mm |

|

Laser cooling method |

Air cooling |

|

Opening depth |

0.01mm-10mm |

|

Opening depth setting resolution |

0.001mm; manually set target opening depth |

|

Galvanometer scanning speed |

>8000mm/s |

|

Product movement method |

Two-position electric worktable (electronic handwheel control/software-automated) |

|

Positioning/error-proofing method |

Visual recognition-assisted positioning + negative pressure/clamping fixture |

|

Software |

MD laser-specific opening vision software; manually set opening depth |

|

Product cleaning |

Vacuum suction dust removal |

|

Vision inspection |

Real-time CCD monitoring |

|

Other auxiliary equipment |

Built-in dust collection system |

|

System integration |

MES and EAP (TCP/IP compatible; supports SECS-GEM communication standards) |

|

Equipment dimensions |

Length: 1150mm * Width: 1000mm * Height: 1750mm |

Main configuration

|

|

Components |

Brief Description |

|

1 |

Laser |

30W, frequency-tunable laser/100,000-hour lifespan |

|

2 |

Galvanometer lens |

Speed: 0-8000 mm/s |

|

3 |

F-θ lens |

Selectable range: 70mm x 70mm, maximum: 150mm x 150mm |

|

4 |

D/A controller card |

16-bit high-performance D/A converter card |

|

5 |

Laser power supply |

Fully digital control |

|

6 |

Computer |

Industrial-grade, P4 2.0G, 4G, 1TB |

|

7 |

Optical system |

Real-time video observation system with preview, CCD > 20 megapixels |

|

8 |

Automatic sample stage |

Automatic stepping XY sample stage, 300 x 300mm travel (accuracy: 0.02mm) |

|

9 |

Fume and dust removal |

Minimum level 2 filtration, 0.3µ particle filtration efficiency ≥ 98% |

|

10 |

Laser safety glass window |

Glass observation window effectively prevents laser damage |

|

11 |

Control unit (MMI) software |

Windows-compatible de-cap software |

Contact: Minder Hu

Phone: 0086-15813334038

Tel: 020-84789496

Email: md@minder-hightech.com

Add: 813,No.43,Xinshuikeng Section, Shixin Road, Dalong street,Panyu District,Guangzhou. Zip:511442