GLOVE BOX CONCEPT

The glove box is a BLVoratory equipment that fills the chamber with high-purity inert gas, circulates and filters O2, H2O, organic gasses and other substances. It is also called vacuum glove box, inert gas protection box, etc. The main function is to remove O2, H2O and organic gas. It is widely used in ultra-pure environments without O2, H2O and dust, such as lithium ion batteries and materials, semiconductors, super capacitors, special lamps, laser welding, brazing, material synthesis, OLED, MOCVD, etc., but also biological applications, such as anaerobic bacteria culture, cell hypoxia culture, etc.

Glove box Principle

The working gas in the glove box is between the chamber and the purification column (H2O and O2 adsorber), and it is closed circulated through pipes, circulation blowers, etc. under the control and monitoring of PLC. When the working gas circulates through the purification column, its moisture and oxygen are adsorbed and then returned to the chamber. As the cycle time passes, the H2O and O2 content of the working gas in the chamber will gradually decrease and eventually reach the index of less than 1 ppm. The purification column will saturate after a certain period of cycle, and can be regenerated and reused.

Schematic diagram of glove box working

INTERNET OF THINGS

①H2O, O2 parameters under control

Real-time monitoring of H2O & 02 data, if there is something abnormal, there is an alarm, send a text message to the mobile phone in time, and the data record is saved up to ten years, which can be queried, downloaded and printed at any time.

② Unattended operation

It can remotely operate the pressure setting of the glove box, vacuum pump, lighting, cycle start and stop, and the site does not need to be on duty during regeneration

③Anomaly monitoring butler service

365 x 24h real-time butler monitors the abnormal situation of each online glove box, guarantees the normal operation of each glove box timely and effectively, and implements preventive online maintenance for each

Digital Glove box System

1. Wireless

2. Extra net

3. Laptop

4. Tablet

5. Cell phone (IOS、Android/Win system)

Glove box Chamber

|

Material |

stainless steel 1.4301 (SUS type 304), thickness 3 mm |

|

Front window |

thick safe tempered glass or 10 mm thick polycarbonate (optional) |

|

Glove port |

hard aluminum alloy or daicel (optional), caliber 220 mm, O-ring seal |

|

Glove |

butyl rubber, thickness 0.4 mm or 0.8mm (optional), diameter 8 inches |

|

Filter |

One filter for each outlet and inlet, specifications<0.3µm |

|

Illumination |

LED light is inside the chimney above the top of the front window |

|

Leakage rate |

<0.01 VOL%/h |

|

Rack |

built-in two-layer adjustable racks |

|

Port |

several standby interfaces |

Gas purification

|

Regeneration |

Siemens PLC automatically controls the regeneration process, effectively removing H2O and O2, single / double purification column system is optional |

|

Control system |

Using Siemens microprocessor, equipped with friendly man-machine operation interface) |

|

Purification column |

purification material: copper catalyst:7kg、Molecular sieve: 8kg; purification ability: deaeration: deoxygenization:80L, dehydration 2.5kg |

|

Vacuum pump |

Rotary vane pump, installed with oil mist filter, oil circulator, and automatic gas ballast control; 12 m³/h (7 cfm) vacuum degree < 2 x10-3mbar dry pump (optional) |

|

Circulation unit |

Oil-free high-speed inverter blower, oil-free; blast capacity 0-100 m³/h |

|

Valves |

high vacuum baffle valve, integrated German Burkert solenoid valve module |

|

Leak rate |

<0.01 VOL%/h |

Main Antechamber

|

chamber |

size |

diameter 360mm, length 600mm (optional diameter 390mm) |

|

material |

304 stainless steel |

|

|

surface |

wire drawing inner surface, painted exterior surface |

|

|

accessories |

tray |

stainless steel mirror processing, sliding tray |

|

chamber door |

double doors, anodized aluminum, with booster structure |

|

|

pressure gauge |

vacuum oil gauge or digital display |

|

|

control |

operation |

PLC control or manual operation |

Mini Antechamber

|

chamber |

size |

diameter 150mm, length 330mm |

|

material |

304 stainless steel |

|

|

surface |

wire drawing inner surface, painted exterior surface |

|

|

accessories |

tray |

stainless steel mirror processing (optional accessories) |

|

chamber door |

double doors |

|

|

pressure gauge |

vacuum oil gauge or digital display |

|

|

control |

operation |

PLC control or manual operation |

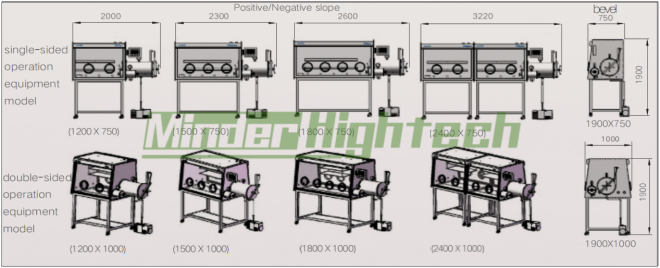

GLOVE BOX INFORMATION

|

type specification |

BLV2000 single side single station |

BLV2000 single side three gloves |

BLV2000 single side double stations |

BLV2000 single side double stations |

BLV2000 double side double stations |

BLV2000 double sides four stations |

BLV2000 double sides four stations |

|

length height-width (MM) |

1200×900X750 |

1500×900 X750 |

1800×900 X750 |

2400×900 X750 |

1200×900 X1000 |

1800×900 X1000 |

2400×900 X1000 |

|

chamber material |

304 stainless steel |

||||||

|

material thickness |

3 mm |

||||||

|

rack height |

950mm |

||||||

|

main antechamber |

Ф360×600 or Ф390×600(mm) |

||||||

|

mini antechamber |

Ф150×330 (mm) |

||||||

|

gloves |

2 PCS |

3 PCS |

4 PCS |

4 PCS |

4 PCS |

8 PCS |

8 PCS |

|

glove port material |

Aluminium oxide/POM |

||||||

|

lights |

1PC |

1PC |

1PC |

2 PCS |

2 PCS |

2 PCS |

4 PCS |

|

rack |

2 layer backboard |

2 layer backboard |

2 layer backboard |

2 layer backboard |

2 layer roof lifting |

2 layer roof lifting |

2 layer roof lifting |

|

filters |

1 inlet and outlet filter |

||||||

|

volume |

0.8m² |

1.0m² |

1.2m² |

1.6 m² |

1.1m² |

1.6 m² |

2.2m² |

|

leak rate |

≤0.001vol%/h |

||||||

|

H2O under |

≤1ppm |

||||||

|

O2 under |

≤1ppm |

||||||

customer side

Different application (made to order):

Contact: Minder Hu

Phone: 0086-15813334038

Tel: 020-84789496

Email: md@minder-hightech.com

Add: 813,No.43,Xinshuikeng Section, Shixin Road, Dalong street,Panyu District,Guangzhou. Zip:511442